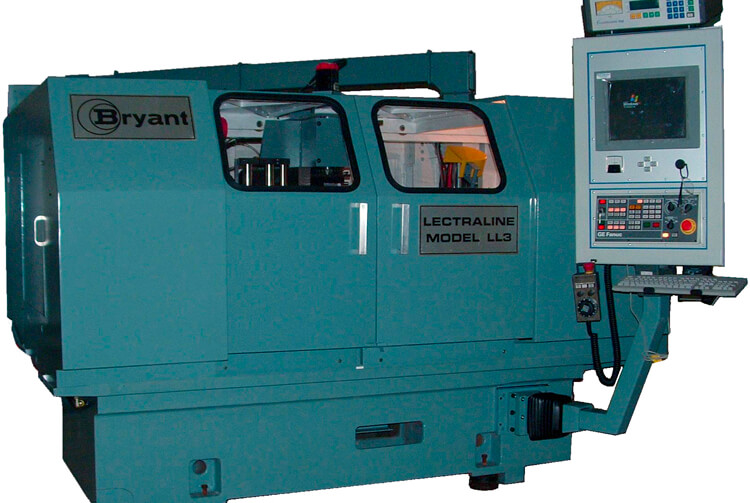

Bryant Remanufactured Lectraline 3 Grinder LL3

The Bryant LL3 CNC Grinder was originally designed to be an advanced, universal, precision tool room grinding machine. But it has made its home on the production floor also. The LL3 can swing parts up to 28 inches (711mm) and grinds bores up to 16 inches (406mm) in length.

Tapers and Rotary Face Grind operations can be done as the LL3's workhead may be swiveled up to 90 °. A sine bar attachment is available to ensure accurate angles.

An optional Bryant Power-Pivot ® Workhead accepts CNC angle settings with a programmable resolution of less than one arc second and CNC B-Axis Control to 100°.

CNC North can source and remanufacture an LL3 for your specific part or rebuild your LL3 to original specifications with state-of-the-art components.

Features

- Simple Operation and Simplified Operator Training

- Design Uses Standardized Tooling and Components

- Multi-Directional and Vector Grinding

- Self Diagnostics

- Fast Cycles

- Energy Efficient

- Quick Set-up and Changeover

- Small Lot Runs or High Production

- CNC Programmable Contour Dress and Grind Profiles

- 'Push-Button' Size Correction

Options

- Automatic Robotic Loading

- Rotary Contour Grinding Capability

- CNC Wheel-Speed Control

- CNC Orthogonal Dress Capability

- Peak Motor-Load Infeed Capability

- Crash Protection Stock Sensor

- Power-Pivot ® Workhead

- In-Process Gaging

- Manual or CNC Work Table Slide Capability

- Multi-Slide Arrangements Available